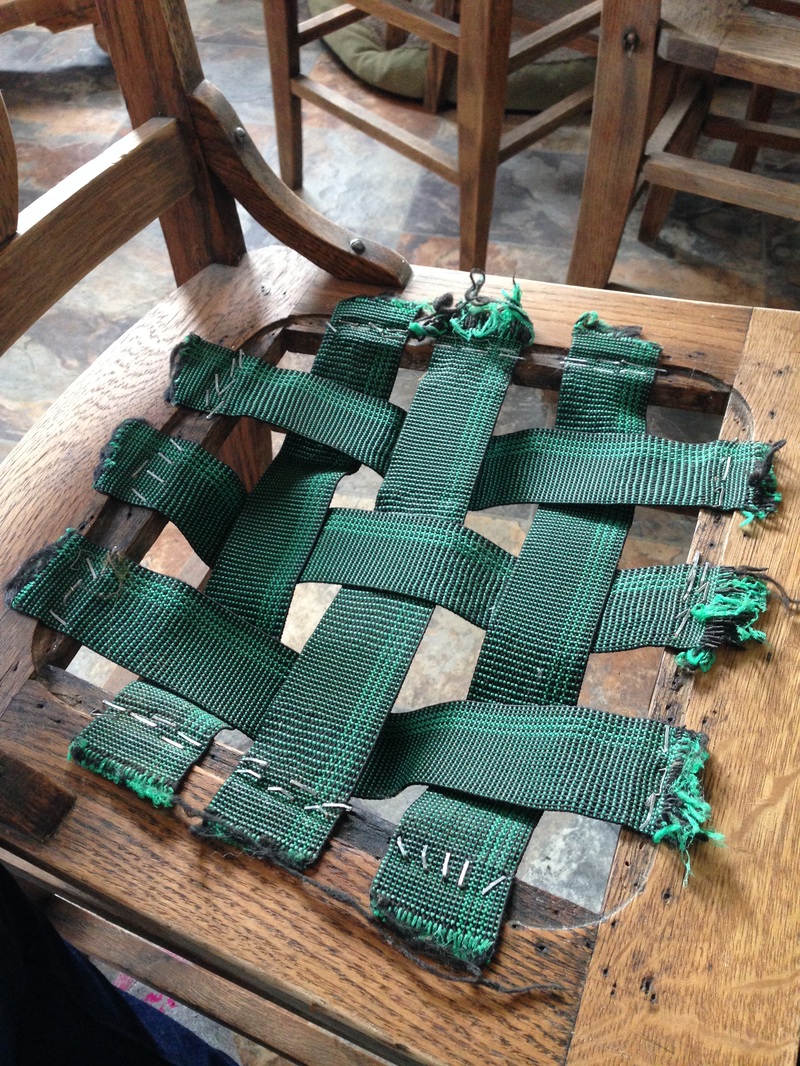

The chairs took much time to prepare. First, the webbing had to be removed. Each end of the webbing had 5-10 staples in it. The chair webbing was apparently done by two different people because one person was meticulous about the placement of exactly 6 staples per side, while the other was haphazard and did not always have the same number of staples either. But, both persons hammered the staples flat after putting the webbing on. I guess they thought they would never have to take it off and wanted it to stay put.

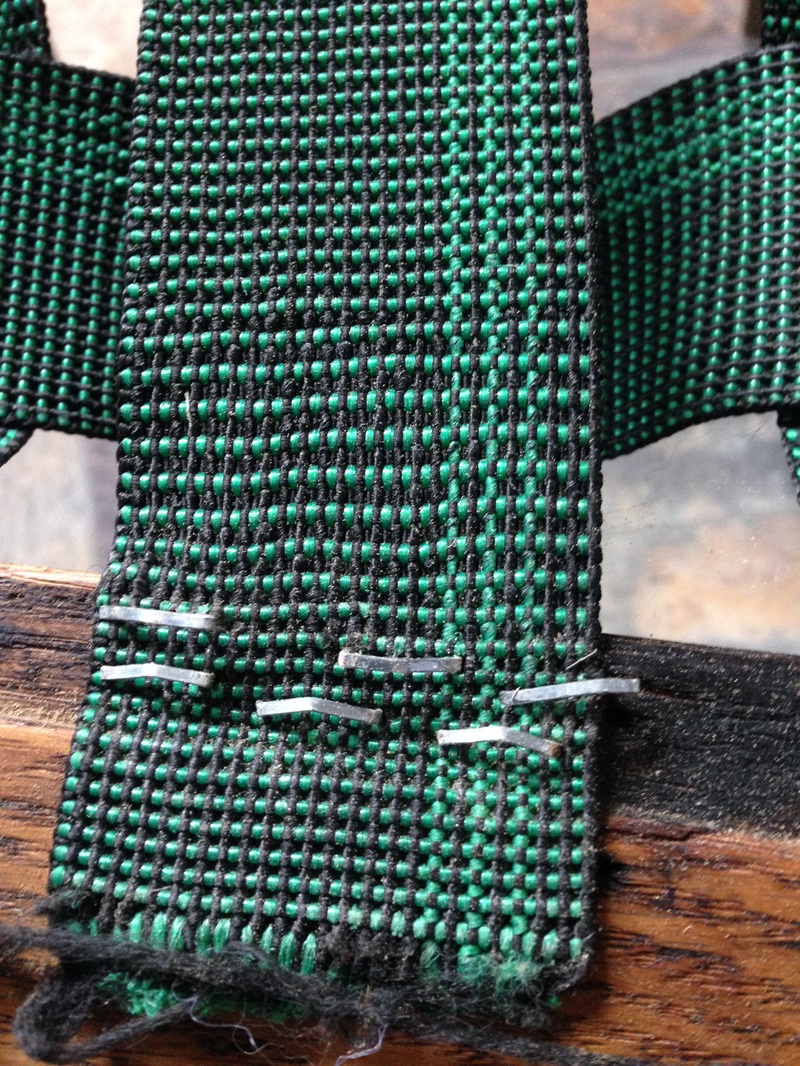

I tried a knife first to slip under the staples and lift them, but it was not a good choice of tool. So, I tried a chisel screwdriver, but it was too thick and the third try, a thinner model of chisel screwdriver worked well. Still, it took some strength and elbow grease to remove those staples. Some broke off because they were actually shattered wtih the hammer, though since they were not stressed, they remained in tact until removed. The shattered staples came off with the webbing. The screwdriver was able to lift the staples but not remove them. I found an old tool that was my father's . I have no idea what that tool is really intended for. It has sharpenable pinchers and a handle that can pinch the hand if not held carefully, but the implement worked extremely well. If too much pressure was applied, the staple was cut, but just a little, just enough to grab and hold the staple and it came right out. Each chair had an average of 72 staples!

There are two chairs with the small nails from a previous seat that are quite embedded and old. I left them in and created a pattern for the upholstery that covers them. I have not been able to find seat foam, hopefully organic latex, anywhere in Alberta. It appears I will have to order some from BC, possibly where I got the organic latex rubber foam for the motorhome. They were fast, effecient and the price was reasonable, that is, if the company is still there.

I had hoped to do a seond coat of the stain finish today, but ended up packing more of the kitchen things that I just unpacked in the kitchen to move back to the farmhouse. Oy!

It will likely be a few days before I get a chance to upholster the seat pads, but I might be able to get the next two coats of stain finish on by then and cut the plywood seat boards out. I bought some new jig saw blades and plywood today, however; it was raining most of the day, again, so I did not attempt to cut them out. I did cut a pattern out, 12 inches wide at the back and 13 and a half at the front to follow the contour of the seat. The foam should be cut this size as well, and I rounded the corners for esthetics. It is a good thing I took the two upholstery courses! This set, the table and six chairs, will be a thing of beauty when it is done. I promise!

RSS Feed

RSS Feed